Cases

3550mm Tissue Paper Machine Technology

This tissue paper production line features crescent-type forming technology and optimized design for manufacturing premium tissue products. The machine ensures efficient fiber utilization, excellent paper characteristics, and stable operation at high production speeds up to 1650 m/min for various tissue paper grades.

Dryer Cylinder Technology For Writing Paper Machine

Dryer cylinders play a critical role in paper drying sections by providing efficient moisture removal through steam heating. Our cylinders feature precision engineering, superior materials, and advanced surface treatments that ensure excellent heat transfer, consistent paper quality, and reliable operation in writing paper production environments.

Writing Paper Machine For High Quality Cultural Paper

Designed specifically for cultural paper manufacturing, this writing paper machine delivers outstanding performance with working speeds up to 600m/min. It ensures perfect paper formation, excellent dimensional stability, and consistent quality for writing paper grades between 50-100gsm with daily production capacity of approximately 290 tons.

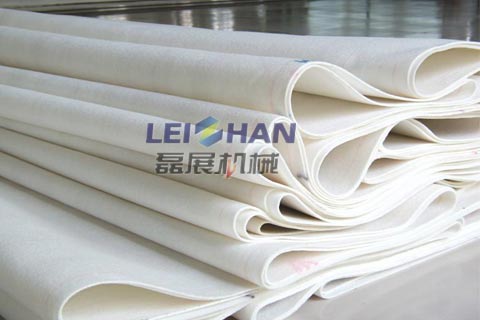

Paper Production Line Machine Paper Mill Felt

Paper mill felt serves as essential clothing in paper machines designed to optimize water extraction, improve paper quality, and ensure smooth web operation. Our precision-engineered felts offer superior drainage capabilities, extended service life, and consistent performance across various paper grades and machine speeds.

Advanced Paper Manufacturing Machine Hydrapulper

Hydrapulpers serve as fundamental equipment in paper production systems effectively processing raw materials into quality pulp. Leizhan’s advanced hydrapulper designs ensure thorough fiber treatment excellent impurity management and optimal chemical mixing for superior results across various applications.

Writing Paper Machine Double Disc Refiner Solutions

Leizhan double disc refiner delivers precise fiber modification for writing paper production. Features hydraulic pressure control wear-resistant discs and automated adjustment systems ensuring consistent refining results and optimal paper quality.

Paper Making Line Machine Underfeed Rewinder

Leizhan 2200mm underfeed rewinder processes 200-600g/m² paper rolls at 600m/min operating speed. Converts φ2000mm parent rolls to φ1500mm finished rolls with 0.3-1.2kg/cm tension control and 25m/min threading speed.

Paper Pulp Making Machine Bale Breaker Manufacturer

Leizhan bale breaker handles 12 t/hr waste paper bales. Features Ø3000×9500mm drum with 30mm screens, 0-12 rpm adjustable speed, and gear drive + VFD system.

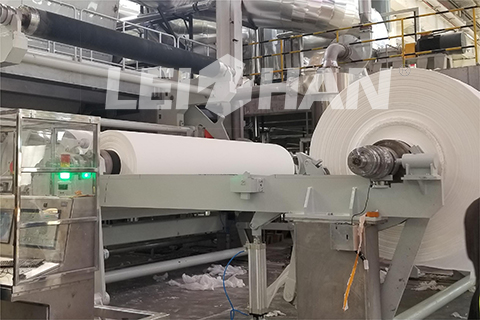

Tissue Paper Machine Equipment Using Site

See Leizhan tissue paper machine equipment operating at high speed. Producing crepe paper from bleached pulp. Features 2850mm web width, speeds up to 1300mpm, and daily production over 52 tons. Dryness reaches 92-94%. Ideal for bulk tissue manufacturing.

Dryer Cylinders in Kraft Paper Making Line

Attain superior paper surface quality with Leizhan’s precision Dryer Cylinders. Featuring ultra-smooth finishes & premium chrome-plated options, they ensure uniform heat transfer & minimal marking. Built tough with HT250 iron & tested to 1.0Mpa for reliable, high-pressure operation.

High-Speed Coreless Paper Rewinder Machine

Converts large full-width paper rolls into finished rolls of specific width, diameter, & tightness. Handles corrugated, kraft, white kraft paper at speeds up to 1500m/min.

Essential Paper Spare Part Sizing Machine

Double-sided film transfer sizing machine applies controlled starch/coating, improving paper properties. A critical, high-performance paper machine spare part upgrade.