Paper Machine Parts

Special Felt For Paper Industry

Special felts used in the paper industry are typically made of high-quality wool or synthetic fibers, and they play a crucial role in the paper making process.

Reeling Machine For Paper Making Line

Reeling Machine is the first complete equipment after the paper machine. The main function of the paper reeling machine is to make the paper evenly reeling, so that the produced paper can be packed into rolls.

Vacuum Pump For Paper Making Line

The vacuum system is an important part of a paper machine. Vacuum pump is the most commonly used equipment in papermaking vacuum systems and is well known to technicians in the papermaking industry.

Boiler For Paper Making Line

Boiler can convert the chemical energy and electrical energy in the fuel into steam with certain heat energy, high-temperature water or organic heat carrier, and help subsequent equipment to dry wet paper.

Press Roll For Paper Making Line

Press roll is the main component of the paper machine press device. A good press roll improves the dehydration efficiency, improves the quality of the paper, and reduces the adverse effects of pressing on the paper.

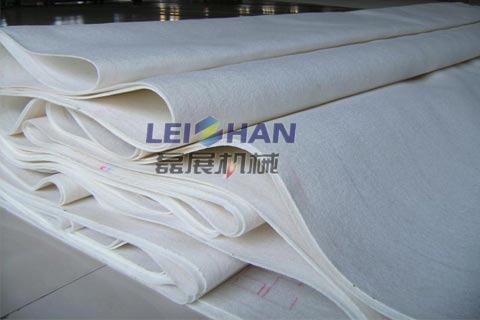

Felt Used In Paper Machine

Felt is mainly used in the paper machine that sends paper to drying part. It is necessary that felt is changed once time for less than three months. Felt that we provided has a good quality.

Dryer Cylinder For Paper Producing Line

Dryer cylinder refers to a machine used in the process of paper making to continuously dry the paper blank after the pulp is formed. Quality of dryer cylinder also affects the quality of finished paper. All heads and journals of dryer cylinder are made of special cast iron. Leizhan will offer you the dryer cylinder with high quality and best price.

Cutting Paper Machine for Toilet Paper Cutting

The paper cutter is a traditional product that is used to handle the cutting needs of paper in the later stages of printing.It can be used for Living paper cutting.

Paper Machine Calender for Paper Making Line

Paper Machine Calender is a device used to improve the gloss of paper, a kind of calendering process, mainly composed of a printed matter conveying mechanism, a mechanical transmission, an electrical control system.

Paper Machine Headbox for Paper Mill

The headbox is a key part of modern paper machines. Its structure and properties are decisive for the formation of the paper and the quality of the paper.

Paper Machine Cylinder Mould

Paper machine cylinder mould mainly used in tissue paper machine or other small capacity paper making line, the total length of the machine is short, working speed slowly, easy to operate.

Doctor Blade For Paper Machine

Doctor blade is a more complex system, has a great impact on the quality of the paper, to improve paper machine performance and paper quality by improving the doctor blade system.