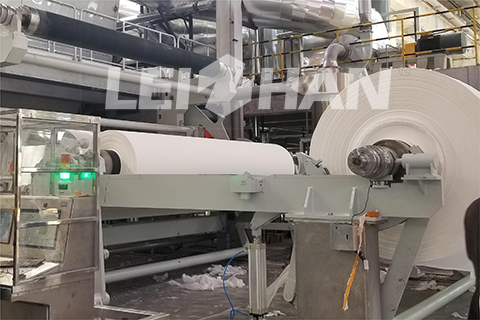

Tissue Paper Making Line

Toilet Paper Making Machine Manufacturer

Are rising costs, unreliable suppliers, or long lead times for tissue paper eating into your profits? Whether you run a hospitality group, a boutique retail chain, a cleaning service, or a specialized packaging company, there’s a smarter solution: bring tissue production in-house with a small-scale toilet paper making machine.

Pulp Screening Machine Heavy Impurity Cleaner

Specifically designed for the rigors of paper mill operations, heavy impurity cleaner efficiently extracts damaging heavy impurities – including gravel, metal fragments, sand, and large ink specks – from all types of pulp, preventing costly downtime and wear.

Pulping Machine Vibrating Screen Machine Price

Optimize your paper pulp preparation process with our reliable Vibrating Screen Machine. Engineered for the rigorous demands of paper mills, the ZSK Series Vibrating Screen Machine efficiently sifts pulp suspensions, removing unwanted particles to ensure a cleaner final product.

25tpd Tissue Paper Production Line

Designed for versatility, they process virgin pulp, wood pulp, or white shavings into premium jumbo rolls for converting into toilet paper, napkins, facial tissues, and handkerchiefs.

Small Scale Toilet Paper Machine For Sale

Perfect for startups or expanding businesses, we also offer tailored pulping solutions for complete production lines. Our small-scale toilet paper machines are trusted by growing enterprises worldwide. Discover the details below.

Waste Paper Mill Machine Drum Screen

Tired of rising operational costs and environmental penalties? Transform waste into resource with intelligent Drum Screen technology – your partner in sustainable water solutions.

Paper Pulp Making Machine Broken Pulper

Designed to tackle rejects from the press section, calender, and paper reel section efficiently, Broken Pulper transforms waste back into valuable fiber with minimal energy input.

Pulp and Paper Equipment High Consistency Hydrapulper

Zhengzhou Leizhan Technology Paper Machinery Co., Ltd. delivers powerful, efficient solutions with its ZDSG Series High-Consistency Hydrapulpers, designed to handle high volumes effectively while being easy to operate and maintain.

Small Tissue Machine for Paper Mill

Leizhan Machinery’s eco-conscious small tissue paper machine delivers energy efficiency and scalability for international businesses.

Waste Paper Making Equipment Slag Lifting Machine

The TZJ Slag Lifting Machine is vital for industries needing clean and efficient water systems. Removes heavy impurities like stones and fibers, protecting equipment from clogs and wear.

Small Scale Tissue Paper Manufacturing Machine

Combining affordability with advanced technology, this small scale tissue paper manufacturing machine empowers you to produce high-demand tissue products efficiently and sustainably.

Broken Pulper for Waste Paper Making Mill

Designed to recover every fiber from waste streams, this broken pulper turns operational scraps into valuable resources—efficiently and responsibly.