Coating Board Paper Making Line

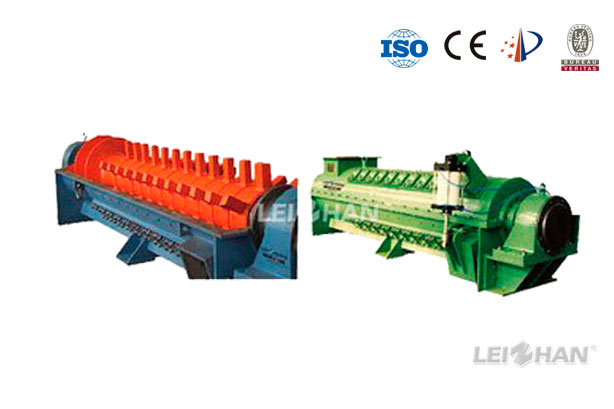

Kneader In Paper Production Line

This kneader specializes in dispersing hot melt impurities including stickies grease wax and plastic particles from paper pulp. It features unique stator rotor design and automatic discharge control for consistent performance and uniform slurry treatment.

High Quality Coating Board Paper Machine

Coating board paper machine is specifically designed for manufacturing high-quality coated board products with superior surface characteristics. The machine features advanced coating technology, precise weight control, and efficient drying systems that ensure optimal production efficiency and product quality.

Hydrapurger For Pulp And Paper Equipment

Hydrapurger equipment plays a crucial role in pulp purification processes by efficiently separating contaminants based on different specific gravity. This system provides early impurity removal protects downstream equipment and ensures consistent pulp quality through automated controlled operation.

Paper Production Line Machine Chain Conveyor Systems

Leizhan chain conveyor handles bulk and bundled materials with 60-600m³/h capacity. Features specially made chains impact-resistant trough plates and efficient operation for reliable waste paper and pulp board transportation.

Tube Paper Machine Systems Manufacturer

Leizhan tube paper machine manufactures paper cores and tubes with precise dimensional control. Features automated winding consistent density and high production efficiency for various industrial packaging applications.

Paper Pulping Machine Double Disc Refiner Technical Specifications

Leizhan double disc refiner delivers precise fiber modification for tube paper manufacturing. Features adjustable gap control uniform energy distribution and automated operation for consistent refining results in paper core production.

Paper Mill Machine Dryer Cylinder Systems

Leizhan dryer cylinder provides efficient thermal transfer and moisture removal in paper drying processes. Features precision dynamic balancing superior surface finish and optimized heat transfer characteristics for consistent paper drying performance.

Coating Paper Making Line Paper Mill Boiler Systems

Leizhan paper mill boiler provides stable steam supply for coating paper lines with high thermal efficiency and low emissions. Features automated pressure control multiple fuel options and reliable operation for continuous paper production.

Coating Paper Machine Paper Mill Felt Specifications

Leizhan paper mill felt delivers precise water removal and sheet support for coating paper machines. Features anti-marking surface optimized drainage geometry and enhanced stability for premium coated paper production at high speeds.

Breast Roll for Paper Machine Spare Part

Leizhan Φ650×3300mm breast roll features 20# steel construction 12.5mm rubber cover 40Cr tempered journals ZWZ bearings and G1.6 dynamic balancing for reliable performance in paper forming sections.

2640mm Output Coating Board Paper Machine

Leizhan coating board paper machine manufactures 50-90gsm grades with 2640mm web width. 300m/min operating speed 400m/min design capability double-layer configuration and AC variable frequency transmission for consistent coating base production.

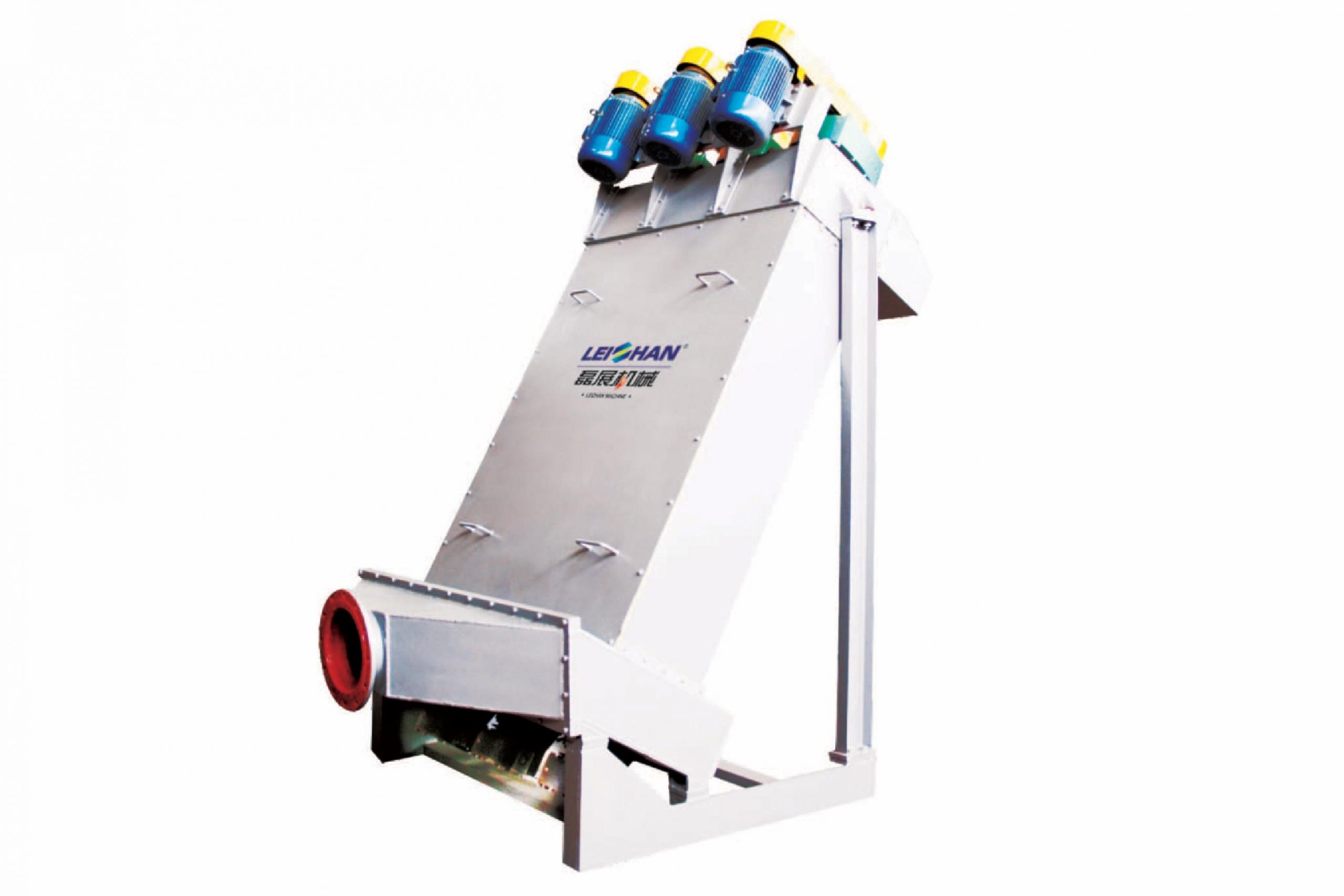

Paper Pulping Machine Inclined Screw Thickener

Innovative inclined screw thickener for paper pulp, combining brush-clog prevention and gravity dewatering. Achieves 14% pulp density at low energy.