Solution

Underfeed Rewinder For Corrugated Paper Manufacturing Machine

This underfeed rewinder processes 2750mm web width handles 3000mm maximum roll diameter and achieves 2000m/min balancing speed. It ensures perfect winding quality for corrugated paper and T paper grades with stable performance and easy operation.

Paper Production Line Machine Disc Disperser

This disc disperser specializes in breaking down hot melt impurities including stickies wax rubber and ink particles from paper pulp. It features customizable disc configurations and automatic lubrication for consistent performance in demanding production environments.

Kneader In Paper Production Line

This kneader specializes in dispersing hot melt impurities including stickies grease wax and plastic particles from paper pulp. It features unique stator rotor design and automatic discharge control for consistent performance and uniform slurry treatment.

3600mm Kraft Paper Manufacturing Machine

This 150t output kraft paper manufacturing machine features 3950mm headbox width 4700mm track gauge and 300m/min working speed. It utilizes fourdrinier forming technology and comprehensive drying systems for efficient kraft paper production.

Screw Press In Paper Production Line

This screw press specializes in pulp washing and concentration through mechanical compression and optimized dewatering technology. It features a specialized screw structure pneumatic back-push assembly and inner dewatering mechanism that ensure consistent performance and easy maintenance.

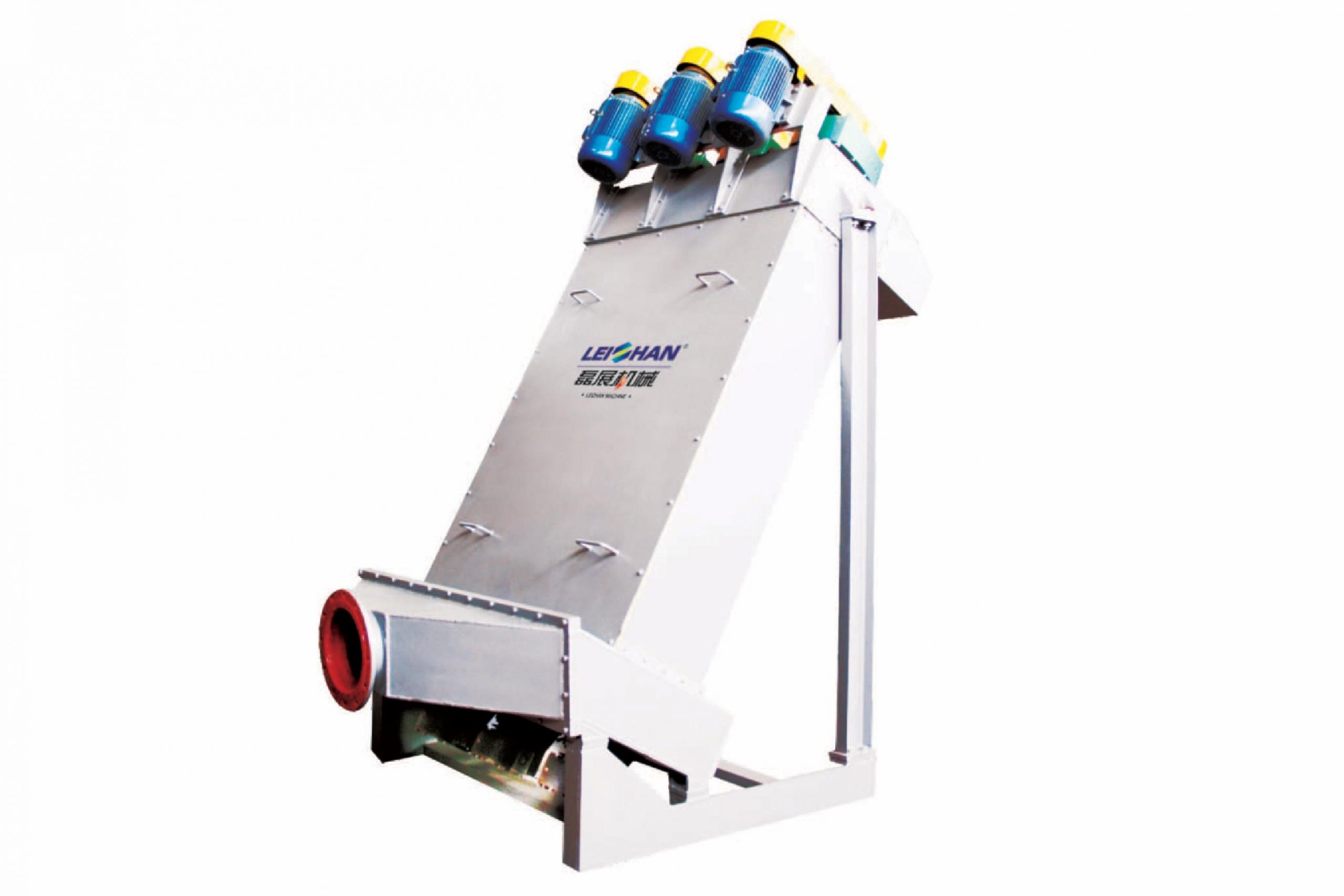

Paper Production Line Inclined Screw Thickener

Inclined screw thickener specializes in pulp washing and concentration through gravity filtration and mechanical conveying. It features anti-clogging technology with synchronized brushes that maintain optimal filtration efficiency and ensure continuous operation in paper production lines.

Flotation Deinking Machine In Paper Pulp Making Line

Zhengzhou Leizhan Technology Paper Machinery Co Ltd with 60-acre production facility and 200 employees delivers quality pulping equipment. Our company possesses advanced manufacturing capabilities and 14 patent technologies serving global markets with complete production lines.

Paper Pulp Making Machine High-speed Stock Washer

Zhengzhou Leizhan Technology Paper Machinery Co Ltd with 60-acre production facility and 200 employees delivers quality pulping equipment. Our company possesses advanced manufacturing capabilities and 14 patent technologies serving global markets with complete production lines.

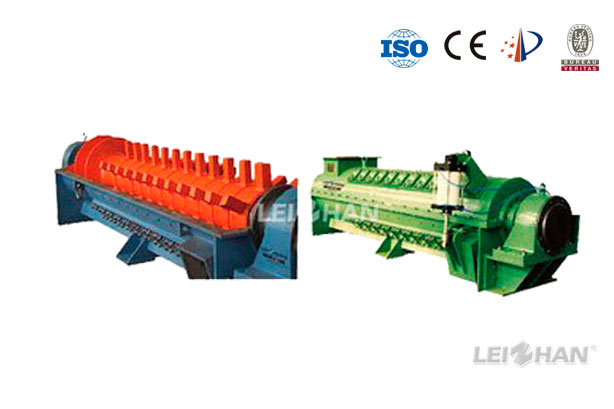

Paper Pulping System Drum Pulper

Zhengzhou Leizhan Technology Paper Machinery Co Ltd with 60-acre production facility and 200 employees delivers quality pulping equipment. Our company possesses advanced manufacturing capabilities and 14 patent technologies serving global markets with complete production lines.

Waste Paper Making Machine Chain Conveyor

Zhengzhou Leizhan Technology Paper Machinery Co Ltd with 60-acre facility and 200 employees including 10 senior engineers delivers quality pulping equipment. Our company possesses 14 patent technologies and advanced manufacturing capabilities serving domestic and international markets with complete production lines.

Pulping Machine Disc Thickener in Paper Mill

The disc thickener specializes in pulp washing and thickening operations, effectively increasing pulp consistency through multi-disc filtration technology. This equipment provides high capacity processing in a compact footprint, making it ideal for space-constrained production facilities.

Paper Manufacturing Machine Inflow Pressure Screen

The inflow pressure screen specializes in pulp purification through advanced screening technology that ensures efficient fiber treatment and contaminant removal. Its innovative design provides seamless operation minimal maintenance and energy efficient performance for various paper production requirements.