Tissue Paper Making Line

Flotation Deinking Machine In Paper Pulp Making Line

Zhengzhou Leizhan Technology Paper Machinery Co Ltd with 60-acre production facility and 200 employees delivers quality pulping equipment. Our company possesses advanced manufacturing capabilities and 14 patent technologies serving global markets with complete production lines.

Paper Pulp Making Machine High-speed Stock Washer

Zhengzhou Leizhan Technology Paper Machinery Co Ltd with 60-acre production facility and 200 employees delivers quality pulping equipment. Our company possesses advanced manufacturing capabilities and 14 patent technologies serving global markets with complete production lines.

Pulping Machine Disc Thickener in Paper Mill

The disc thickener specializes in pulp washing and thickening operations, effectively increasing pulp consistency through multi-disc filtration technology. This equipment provides high capacity processing in a compact footprint, making it ideal for space-constrained production facilities.

Paper Mill Roll For 50T Output Tissue Paper Machine

The paper roll is essential in tissue paper manufacturing for determining sheet formation quality and operational stability. Its advanced construction with rubber coating and precision balancing ensures excellent surface characteristics and consistent performance throughout the production process.

Vibrating Screen For 50t Output Tissue Paper Machine Systems

Vibrating screen equipment plays a vital role in tissue paper production by providing efficient pulp screening and fiber separation. This essential component utilizes advanced vibration technology to ensure optimal debris removal and maintain consistent pulp quality throughout the manufacturing process.

Inflow Pressure Screen Technology For Tissue Paper Machine Efficiency

Inflow pressure screens serve as essential equipment in tissue paper manufacturing by providing final-stage pulp purification before the forming section. This critical component ensures optimal fiber quality through precise screening technology that removes contaminants and maintains consistent stock consistency for superior paper formation.

50t Output Tissue Paper Machine For Quality Tissue Production

50t output tissue paper machine specializes in manufacturing premium creped tissue products with excellent softness and absorption properties. The machine features optimized design and precise control systems that ensure consistent performance and high production efficiency.

Paper Pulping Machine Heavy Impurity Cleaner

Heavy impurity cleaner equipment plays a crucial role in pulp purification systems by effectively removing dense contaminants that can damage downstream equipment. This essential component operates at high consistency levels reduces system complexity and ensures reliable performance throughout the stock preparation process.

Tissue Paper Machine Systems Vibrating Screen

Vibrating screen equipment plays a vital role in tissue paper production by providing efficient pulp screening and fiber separation. This essential component utilizes advanced vibration technology to ensure optimal debris removal and maintain consistent pulp quality throughout the manufacturing process.

Stock Preparation Line Machine Inflow Pressure Screen

Inflow pressure screens serve as essential equipment in tissue paper manufacturing by providing final-stage pulp purification before the forming section. This critical component ensures optimal fiber quality through precise screening technology that removes contaminants and maintains consistent stock consistency for superior paper formation.

Pulp Pump Technology For Tissue Paper Machine

Pulp pump equipment plays a vital role in tissue paper production by delivering consistent pulp stock to the forming section. This essential component features low-pulse operation precise flow control and robust construction that ensures reliable performance and maintains optimal paper quality throughout the manufacturing process.

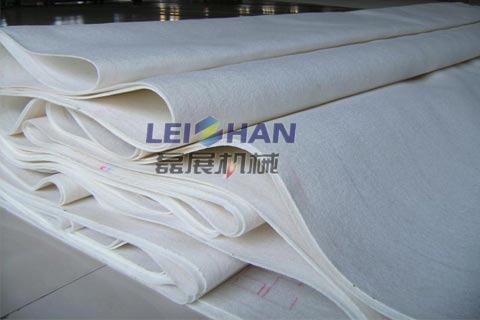

Durable Felt For Tissue Paper Making Line

Felt serves as critical clothing in tissue paper machines designed to optimize water extraction, improve tissue quality, and ensure smooth web operation. Our precision-engineered felts offer superior drainage capabilities, extended service life, and consistent performance for tissue grades at various machine speeds.