Solution

Inflow Pressure Screen Technology For Tissue Paper Machine Efficiency

Inflow pressure screens serve as essential equipment in tissue paper manufacturing by providing final-stage pulp purification before the forming section. This critical component ensures optimal fiber quality through precise screening technology that removes contaminants and maintains consistent stock consistency for superior paper formation.

50t Output Tissue Paper Machine For Quality Tissue Production

50t output tissue paper machine specializes in manufacturing premium creped tissue products with excellent softness and absorption properties. The machine features optimized design and precise control systems that ensure consistent performance and high production efficiency.

Paper Pulping Machine Heavy Impurity Cleaner

Heavy impurity cleaner equipment plays a crucial role in pulp purification systems by effectively removing dense contaminants that can damage downstream equipment. This essential component operates at high consistency levels reduces system complexity and ensures reliable performance throughout the stock preparation process.

Stock Preparation Line Light Impurity Separator

Light impurity separator equipment plays a vital role in pulp purification systems by effectively removing lightweight contaminants through advanced vortex separation technology. This essential component ensures improved pulp quality and protects downstream equipment while operating efficiently across various consistency ranges.

High Quality Coating Board Paper Machine

Coating board paper machine is specifically designed for manufacturing high-quality coated board products with superior surface characteristics. The machine features advanced coating technology, precise weight control, and efficient drying systems that ensure optimal production efficiency and product quality.

Underfeed Rewinder in Corrugated Paper Making Line

This underfeed rewinder handles jumbo rolls of corrugated paper or board converting them into market-ready finished rolls. It offers coreless operation modular layout and vibration-dampened drives to maintain precision at speeds up to 1300 m/min.

Tissue Paper Machine Systems Vibrating Screen

Vibrating screen equipment plays a vital role in tissue paper production by providing efficient pulp screening and fiber separation. This essential component utilizes advanced vibration technology to ensure optimal debris removal and maintain consistent pulp quality throughout the manufacturing process.

Stock Preparation Line Machine Inflow Pressure Screen

Inflow pressure screens serve as essential equipment in tissue paper manufacturing by providing final-stage pulp purification before the forming section. This critical component ensures optimal fiber quality through precise screening technology that removes contaminants and maintains consistent stock consistency for superior paper formation.

Pulp Pump Technology For Tissue Paper Machine

Pulp pump equipment plays a vital role in tissue paper production by delivering consistent pulp stock to the forming section. This essential component features low-pulse operation precise flow control and robust construction that ensures reliable performance and maintains optimal paper quality throughout the manufacturing process.

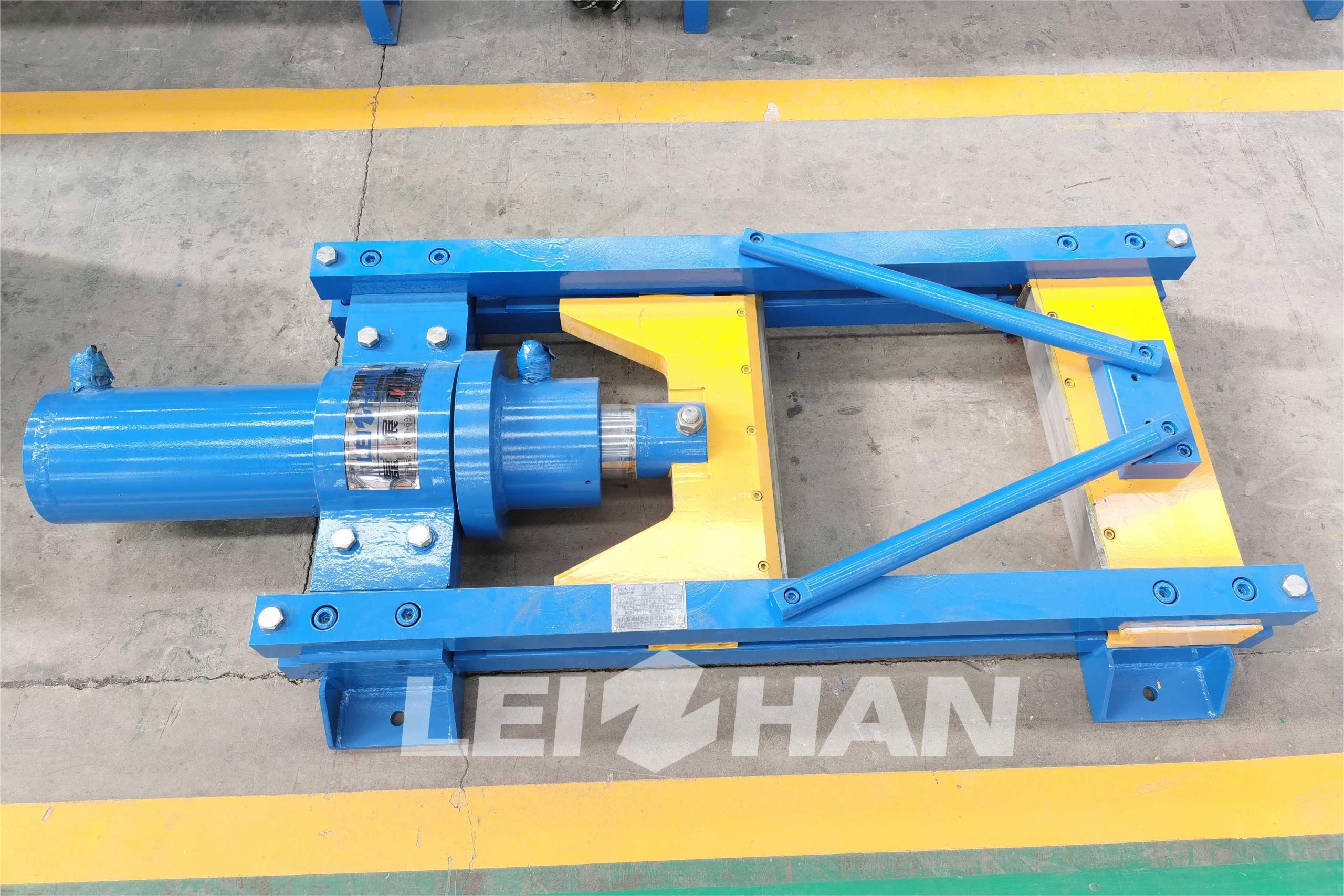

Paper Mill Grapple For Pulp And Paper Equipment

Paper mill grapple equipment serves as a crucial component in waste removal systems designed to efficiently extract large contaminants from pulping equipment. This specialized tool features pneumatic operation and optimized grabbing mechanics that significantly reduce cleaning time while improving overall system efficiency in paper recycling processes.

Paper Recycling Machine Rope Cutter Technology

Rope cutter equipment plays a vital role in waste handling systems by efficiently cutting entangled ropes and materials extracted from pulpers. This critical component ensures continuous operation prevents system blockages and maintains optimal efficiency in pulp and paper production processes.

Pulp And Paper Equipment Drum Screen Technology

Drum screens play a critical role in pulp purification systems by effectively separating large light impurities from paper stock. Our drum screen equipment ensures high screening efficiency, reliable operation, and excellent fiber preservation through advanced design and optimal water spray systems for superior pulp quality.