Solution

Paper Mill Paper Pulp Machine Preparation Line For Paper Making Project

We offer whole paper making line for paper mill, welcome email us to get more machine details and price. Email: leizhanworld@gmail.com

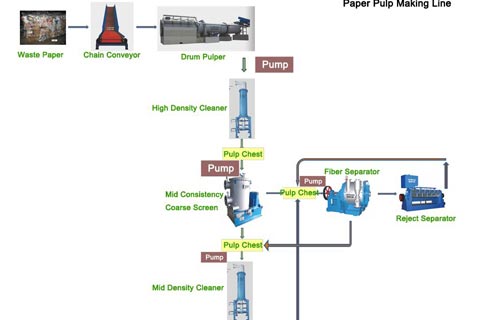

Paper Pulp Making Line For Corrugated Paper Making Project

Our company can offer paper mill the whole paper making line, welcome email us if you are interested in papermaking. Email: leizhanworld@gmail.com

Double Layer Kraft Paper Machine For Paper Mill

Introducti…

Dry Screenign System for Bale Breaking

Bale Breaker is mainly used for waste paper bales breaking and selecting. Welcome email us : leizhanworld@gmail.com

Pulp Machine High Density Cleaner

High Density Cleaner can clean pulp with high consistence,it’s a ideal choice for paper company to improve quality ,grades and clean pulp , specially the effect to clean waste pulp is better.

Sludge Dewatering Machine

The control of municipal sewage and papermaking sewage has already becoming the first problem of every city and company.The key link of sludge’s concentration and Dewatering is continuous research and exploration. Our company in these years product the HD series Sludge Dewatering Machine through introduce and absorb mature experience and technology

Installation and Adjustment of In-Flow Pressure Screen

In-Flow Pressure Screen is an advanced pulp screening equipment in the modern world. It has the characteristics of screening quality, mushroom ability and pulp flow pulse bottom. It is suitable for fine screening equipment of pulp, straw pulp and waste pulp, especially for pre-filing screening equipment of paper machine.

High Grade Facial Paper Machine for Sale

High Grade Facial Paper Machine for sale, which Machine mainly produce high grade living paper, it has reasonable price and advance technology

Tissue Paper Roll Machine for Paper Mill

The Tissue Paper Roll Machine is a professional equipment for producing tissue paper ,toilet paper, napkins, and facial tissues.

Chain Conveyor for Pulp Board Conveying

Chain Conveyor is an indispensable equipment for pulp board conveying at paper mill, Chain Conveyor’s conveying effect is the first step in the pulping process

Paper Making Felt for Paper Conveying

Fabric felt Mainly used for paper forming, Wet paper press dehydration and conveying in the paper industry. There are wet felt, Up felt and dry felt

Waste Paper Coarse Screening Machine Drum Pulper

The drum pulper combines pulping and coarse screening into one. Drum Pulper has the characteristics of simple structure, practicality and high efficiency.

Page Links: First PagePrevious7576777879808182838485NextLast Page