Solution

High Performance 3600mm Writing Paper Machine

The Leizhan Writing Paper Machine excels in producing lightweight and coated writing papers. Featuring a 3600mm sheet width, 4150mm wire, and high operational speeds. Designed for stability at 800m/min, balanced for 900m/min. See large-volume efficiency.

Tissue Paper Machine Calender Precision Control Operation

Tissue paper machines manufacture bath tissue, towels, napkins, and facial tissue. After forming, drying, and creping, the web passes through a calender. This unit, featuring heated rolls under controlled pressure, is vital for final sheet calibration, influencing smoothness, caliper, bulk, and overall tactile quality before winding and converting.

Reeling Machine in Paper Machine Production Lines

Engineered for paper manufacturing, this horizontal pneumatic reeling machine supports rolls up to φ2800mm. It guarantees precise winding, smooth operation, and seamless integration into kraft paper or packaging production lines, enhancing overall workflow efficiency.

4300mm Wide High Speed Kraft Paper Production Machine

This kraft paper machine offers a production range of 100-300g/m², with a max speed of 350m/min and a daily capacity of 278T/D. Its robust design ensures long-term performance for kraft paper manufacturers.

Corrugated Paper Machine Equipment Chain Conveyor System

This chain conveyor moves 20 rolls/hour with a 3-inch core, compatible with 800-2800mm widths. Integrated into 4300mm rewinder lines, it requires just 1 operator for labeling, inspection, and data verification, streamlining post-production logistics.

Pulp Machine Equipment Pulp Pump Supplier

The pulp pump is crucial in paper manufacturing, ensuring efficient pulp movement. It supports paper machine equipment by maintaining steady flow and reducing blockages. Leizhan provides durable pulp pumps for optimal paper production performance.

Tissue Paper Machine Equipment from Leizhan Paper Machine Supplier

Leizhan’s tissue paper machine offers end-to-end solutions, including design, equipment supply, and installation from the headbox to the reel. We support automation and electrical systems, enabling production of 10.5–28 g/m² tissue at speeds up to 1300 m/min.

Heavy Slag Extruder Pulp Machine Technical Specifications

The Heavy Slag Extruder from Zhengzhou Leizhan Technology efficiently dewaters and thickens pulp tailings, featuring compact design, low costs, and high adaptability for industrial use.

Pulp Machine Sludge Dewatering Machine Specifications

The HD Series Sludge Dewatering Machine optimizes sludge concentration for industries such as paper making and municipal projects, offering high efficiency and reduced operational costs.

Leizhan Pulp Machine Agitator for Paper Industry

Leizhan’s JB Agitator sustains pulp suspension in paper making chests, enabling even fiber distribution. Features angle-adjustable blades for varying slurry concentrations. Enhances pulp machine performance with efficient cyclic stirring.

Pulp Machine Heating Screw Conveyor Technology

Heating Screw Conveyor is essential for pulp machines handling high-consistency stock. It conveys pulp to mixers while heating it and injecting bleach solution. Optimized blades ensure loose pulp for even heating. The efficient heating system provides uniform temperature with lower steam consumption. Motor speed adjusts via frequency control.

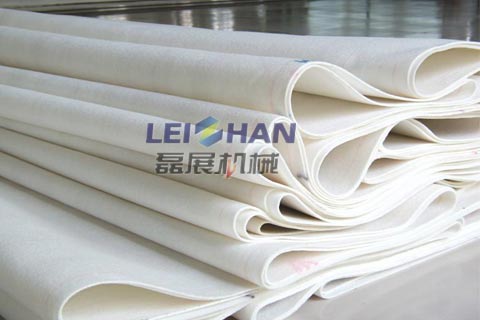

Paper Mill Felt for Vital Machine Spare Parts

Paper mill felt is a vital permeable fabric belt central to paper machines. It carries the wet paper sheet through key stages (forming, pressing – including screw presses, initial drying), facilitating water removal, sheet consolidation, surface finish, and smooth runnability.