Solution

Boiler for Tissue Paper Making Line

Leizhan industrial boilers provide reliable steam for tissue drying achieving 92-94% sheet dryness at 1300m/min. Features automated pressure control fuel flexibility and rapid response systems ensuring consistent 52T/D tissue production.

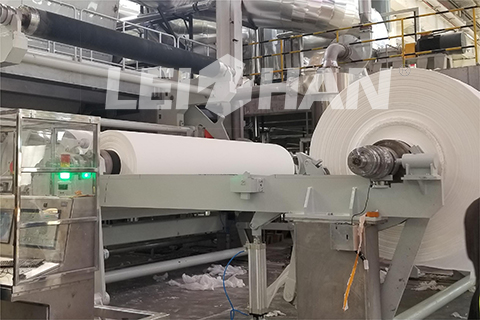

Paper Roll for Tissue Paper Making Machine Equipment

Leizhan high-performance paper rolls maintain web integrity throughout tissue manufacturing. Precision components ensuring proper sheet transfer and drying at 1300m/min operating speeds with 1400m/min balancing capability.

25GSM Tissue Paper Making Machine Manufacturer

Leizhan crescent former tissue machine manufactures 25GSM creped paper using bleached market pulp. 2850mm width 52T/D capacity 1300m/min speed achieving 92-94% dryness. Dynamic balancing at 1400m/min.

Paper Machine Coarse Screening Reject Chest Agitator

Leizhan 20m³ SS304 reject chest agitator handles 3-5% consistency stock. Features adjustable blades V-belt drive SKF/FAG bearings SEW/Flender gearbox ABB/Siemens motor/VFD gland packing and Safematic seal water system.

Paper Machine Equipment Light Impurity Separator Solutions

Leizhan Light Impurity Separator processes 30 BDt/day secondary coarse screen rejects at 2.0-2.5% consistency. Features 2.8-4.0mm holes 30-40% open area SS304 construction V-belt drive auto greasing 0.2-0.3MPa pressure and reject valves.

Paper Making Machine Coarse Screen

Leizhan coarse screen handles 235 BDt/day pulp at 2.8-3.2% consistency. Features 0.6mm slots 1.8m² SS316L chrome basket SS304 rotor 0.2-0.3MPa pressure auto-greasing V-belt drive and reject valves.

Paper Recycling Machine Ragger Solutions

Leizhan ragger removes wires plastics and non-pulpables at 0-60 m/hr speed. Features rotating base alignment dual carbon steel drums with gear drives and robust frame construction for 24/7 operation.

Paper Recycling Machine High Density Cleaner Manufacturer

Leizhan High Density Cleaner handles 6000 L/min pulp flow at 3-5% consistency. SS304 construction with ceramic cones pneumatic knife valves 0.3-0.4 MPa inlet pressure and 0.12-0.15 MPa pressure drop.

Bale Feed Conveyor in Paper Making Line

Leizhan bale feed conveyor transports 12 t/hr waste paper bales at variable speeds (0-10 m/min). 1600mm width 600mm side walls 28m total length (23° incline). Equipped with VFD gear drive and dual safety walkways.

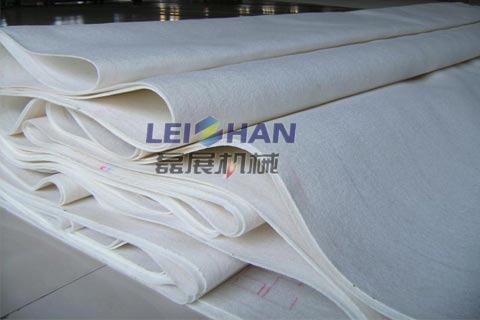

Paper Machine Spare Part Felt Solutions

Leizhan designs industrial paper machine felts for forming press dryer applications. Custom widths 1-12m lengths ≤200m permeability 50-300 CFM compatible with machine speeds ≤1200m/min. Polyester/polyamide construction.

Kraft Paper Machine Technical Details

Leizhan kraft paper machine manufactures kraft/corrugated paper on a 2600mm web. Processes Φ2000mm jumbo rolls into Φ1500mm finished rolls at 600m/min operating speed, with 800m/min balancing capability.

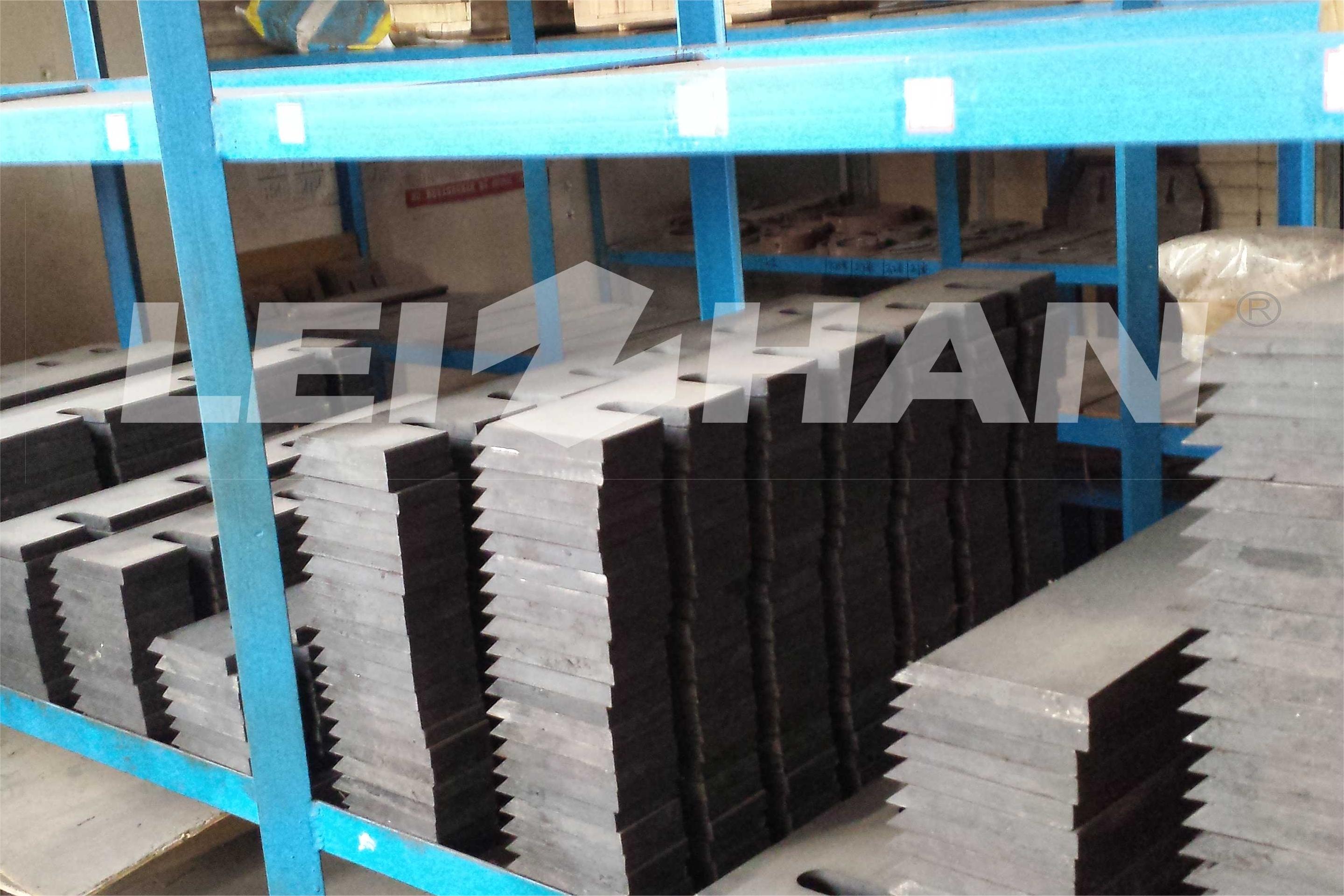

3600mm Writing Paper Machine Doctor Blade

Designed for writing paper machines: G-shaped 304 stainless steel body with drainage. Carbon fiber blade with stainless steel supports. HT150 bearing housing with spherical/sliding bearings ensures uniform pressure. Fixed design with manual lift and self-weight loading.