Kraft Liner Paper Making Line

Leizhan Paper Machine Filter

In the paper machine manufacturing process, efficient filters are the key link to ensure the quality of the raw liquid and the stable operation of the machine. Leizhan paper machine filter provides strong protection for the paper machine process with its excellent filtration effect and reliable working principle.

Φ2000mm Kraft Paper Making Line Rewinder

After Leizhan Machinery understands the specific parameters and working principle of the customer’s product, we can customize the rewinder for you.

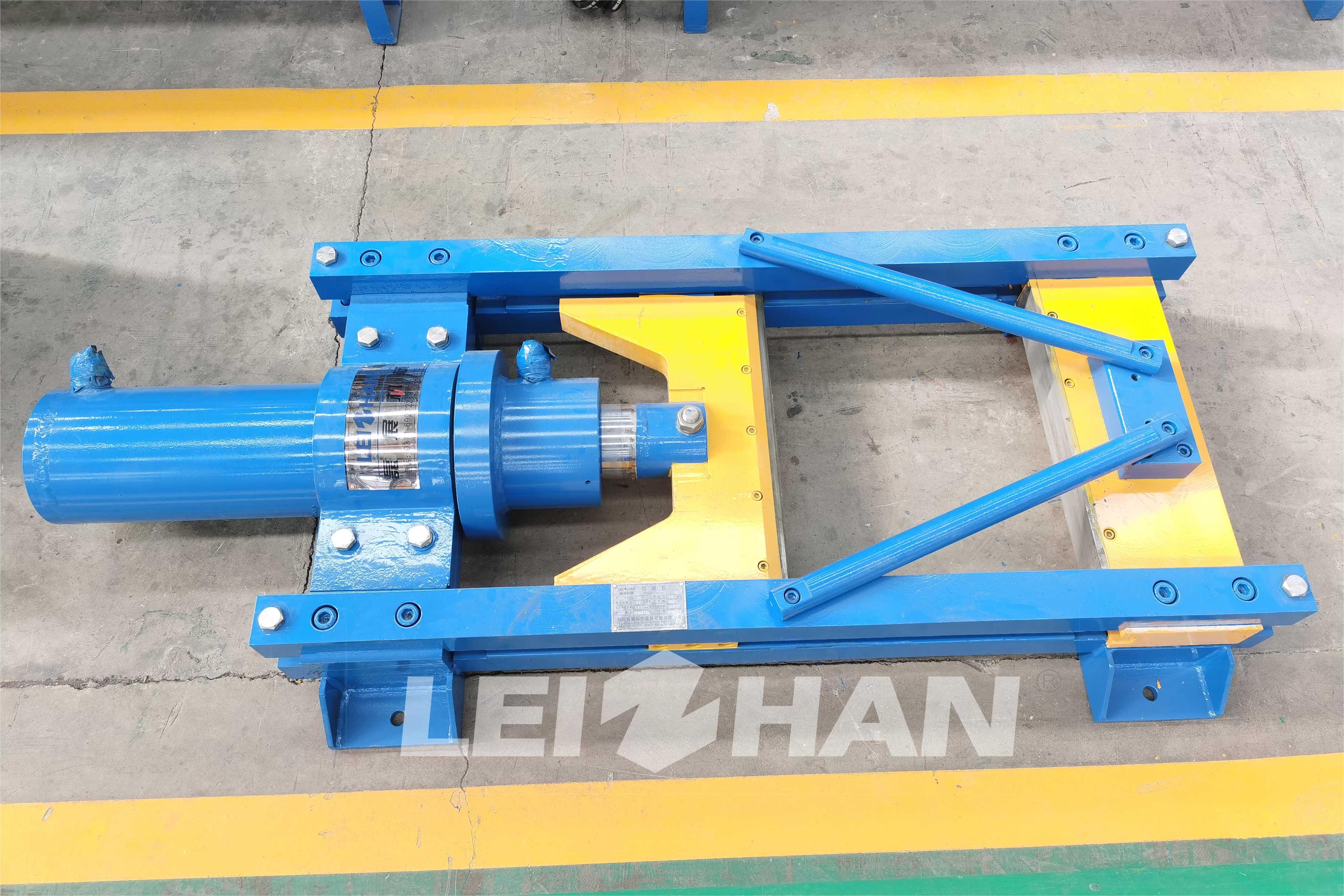

Ragger And Rope Cutter In Paper Pulping

As a reputable manufacturer, our ragger and rope cutter are essential equipment in paper pulping lines, including D type continuous pulping systems for paper mills. Both machines deliver outstanding performance and reliability.

Waste Paper Recycling Machine For Paper Mill

Waste paper is ubiquitous in our daily lives, prompting an increasing number of customers to consider establishing paper mills for resource recycling.

Pulp Making Drum Pulper

The stock preparation machine known as a drum pulper is an essential component in the waste paper recycling pulp making line. This drum pulper is specifically designed for use in high-capacity packaging paper production lines. It enables continuous low maintenance costs, and minimizes fiber loss during operation.

Recycling Paper Machine Cleaner for Paper Pulping

Our cleaner is specially designed to deliver unmatched cleaning performance, effectively removing contaminants and residues from paper machine components to ensure peak operational efficiency and product quality.

Bale Opening Machine For Paper Mill

Bale Opening Machine represents a paradigm shift in the paper production landscape, offering unmatched efficiency, precision, and sustainability.

Chest Agitator For Paper Recycling Line

The chest agitator plays a pivotal role in regulating the temperature of the pulp slurry and promoting effective chemical reactions. By promoting thorough agitation, it helps to disperse heat generated during pulping and ensures proper distribution of added chemicals, thereby optimizing the efficacy of chemical reactions.

Sludge Dewatering Machine for Pulping Line

The sludge dewatering machine aids in reducing the volume of sludge, decreasing its moisture content, and improving its transport efficiency. Additionally, it helps reduce potential secondary pollution to water sources and the atmosphere.

Paper Roll Production Machinery

The Cresent former high speed tissue paper machine is specifically designed for the production of tissue paper, wet napkins, kitchen towels, and paper diapers. It is accredited with international ISO and BV certifications, underscoring its quality and performance. Below are its primary technical specifications:

Automatic Paper Machine Fiber Deflaker

The paper machine fiber deflaker plays a crucial role in the paper production process, especially in waste paper treatment. It is a key piece of equipment that can greatly enhance the physical properties of paper, making it an essential tool for improving the overall quality of paper products.

Paper Pulp Making Machine Hydrapurger

The Hydrapurger, in conjunction with the trash well, is utilized to remove a substantial volume of lightweight material and a minimal amount of heavier substances from the pulper during the waste paper treatment process in the pulp and paper industry.