Kraft Liner Paper Making Line

Paper Machine Spare Parts Of Dryer Cylinder

The dryer cylinder is a hollow cylinder made of cast iron with covers at both ends. It consists of a cylinder block and cylinder heads at both ends. When working, steam passes through the interior to dry and iron the conveyed paper.

Double Disc Refiner For Paper Making Line

Double-disc refiner can be applied in the continuous refining section of the paper making industry. It can be applied for continuous beating of original pulp, chemical wood pulp, mechanical pulp and waste paper pulp.

Paper Pulp Machine D Type Hydrapulper

D-type Hydrapulper is mainly applied to crush various pulp boards, broken paper and various waste papers. Its main features: the Vaux rotor is deviated from the center position, making the contact between the pulp and the rotor faster and with higher frequency.

Industrial Steel Chain Conveyor For Paper Making Line

Leizhan can make the head and tail of the two chain conveyor into overlapping mixed chains, so that the waste paper bundles that need to be transported are in a dynamic transition state, so that no materials are retained on the conveyor line.

Inflow Pressure Screen For Pulp And Paper Machine

Inflow pressure screen is applied for fine pulp in pulp and paper making systems and screen screening in front of the paper machine. The equipment is mainly composed of shell, rotor, screen drum, transmission device, lifting device, etc.

Small Production Capacity Kraft Paper Making Line

As energy conservation and emission reduction become more and more popular, it has become a consensus in the industry that paper companies reduce water consumption, reduce electricity consumption, and reduce gas consumption.

Industrial Cleaner For Paper Industry

Leizhan has cleaner with different concentrations, and the corresponding slag removal effects and slag removal objects are different. We can design corresponding cleaner according to customers’ needs.

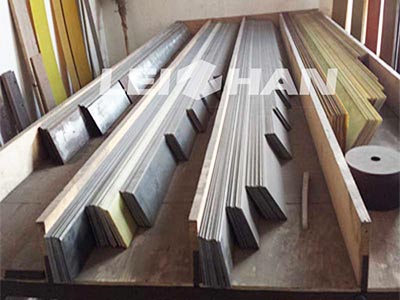

Doctor Blade of Paper Machine Press Part

Press part is a step of continuous dehydration. The paper web that has been formed in the wire part is pressed to remove most of the bound water, so that the dryness reaches 35~40%.

Middle Consistency Pressure Screen For Paper Pulping Machine

The M.C. pressure screen is a device that continuously screens pulp under pressure in a completely closed state. During operation, unscreened pulp enters the upper part of the pressure screen, and heavier objects are separated under the action of centrifugal force.

75T Kraft Paper Machine Production Line

This paper machine is 3600 Fourdrinier multi-cylinder paper machine, which is mainly used to produce 40-100g/m2 kraft paper, etc. All products are roll paper. Transmission mode is AC motor variable frequency speed regulation part drive.

Light Impurity Separator For Paper Pulping Machine

Light impurity separator is a fully automatic control slag discharge type separation equipment. It has the advantages of high speed, smooth operation, fully sealed inlet and outlet systems, low noise, and good separation effect.

Paper Machine Spare Part Of Reeling Machine

Reeling is a completed process, which is the process of reeling and slitting the rolled paper as required. The reeling process and equipment are actually very complex according to the depth involved.