Solution

Hydrapurger For Pulp And Paper Equipment

Hydrapurger equipment plays a crucial role in pulp purification processes by efficiently separating contaminants based on different specific gravity. This system provides early impurity removal protects downstream equipment and ensures consistent pulp quality through automated controlled operation.

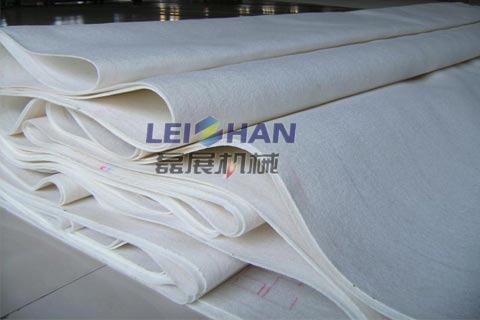

Durable Felt For Tissue Paper Making Line

Felt serves as critical clothing in tissue paper machines designed to optimize water extraction, improve tissue quality, and ensure smooth web operation. Our precision-engineered felts offer superior drainage capabilities, extended service life, and consistent performance for tissue grades at various machine speeds.

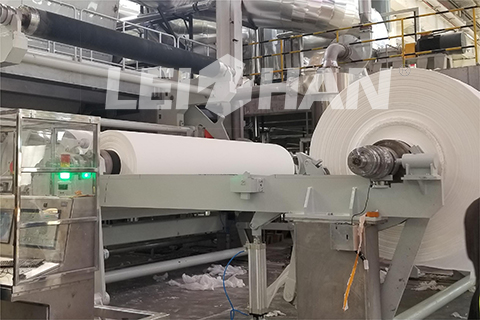

15T Output Tissue Paper Manufacturing Machine

Designed specifically for tissue paper production, this tissue paper machine delivers outstanding performance with optimized fiber utilization and energy efficiency. It ensures perfect paper formation, excellent softness characteristics, and consistent quality for various tissue grades with daily production capacity of 15 tons.

Paper Pulping Machine Cleaner in Paper Mill

Paper mill cleaners are critical components in pulp processing systems that ensure the removal of various impurities from paper stock. Our comprehensive cleaner solutions effectively separate both heavy and light contaminants through advanced hydrocyclone technology, protecting downstream equipment and guaranteeing consistent pulp quality for superior paper production.

Paper Mill Pulper For Paper Recycling Line

Paper mill pulpers serve as the heart of paper recycling operations, efficiently breaking down various paper materials into reusable fibers. Our pulper systems feature innovative designs that ensure optimal fiber separation, reduced energy consumption, and reliable performance for both waste paper and broke processing applications.

Stock Preparation Line D Type Hydrapulper

Description: This hydrapulper specializes in rapid fiber separation and efficient impurity handling. The D-type design creates optimal slurry movement, accelerates pulping, collects heavy contaminants, and integrates seamlessly with deslagging systems to maximize overall production efficiency and equipment longevity.

Drum Pulper in Toilet Paper Making Line

Drum pulper enables continuous pulping and coarse screening under high consistency. It protects fiber integrity, lowers power consumption, simplifies operation, and enhances slag removal. Perfect for mills aiming to optimize performance and reduce cost.

Paper Production Line Machine Bale Breaker Systems

Leizhan bale breaker handles waste paper bale breaking and impurity removal with Φ3000-4250mm drums. Features dry processing 220-1500t/d capacity and dual motor drive for reliable operation and downstream equipment protection.

Paper Production Line Machine Chain Conveyor Systems

Leizhan chain conveyor handles bulk and bundled materials with 60-600m³/h capacity. Features specially made chains impact-resistant trough plates and efficient operation for reliable waste paper and pulp board transportation.

40TPD Liner Paper Production Reeling Machine Systems

Leizhan reeling machine provides precise winding for 40TPD liner paper production. Features pneumatic control φ1100mm drum and high-hardness surface finish for consistent roll formation and quality packaging paper output.

Leizhan 40T Daily Production Liner Paper Machine

Leizhan liner paper machine manufactures 70-150gsm facing paper with 40T daily output using 100% recycled fiber. Features AC frequency drive 2600mm wire width and precision dryness control for quality packaging paper production.

Tissue Paper Machine Pressure Screen Systems

Leizhan pressure screen provides efficient pulp screening for tissue paper manufacturing. Features high capacity operation minimal fiber loss and automated control for consistent pulp quality in tissue production lines.