Solution

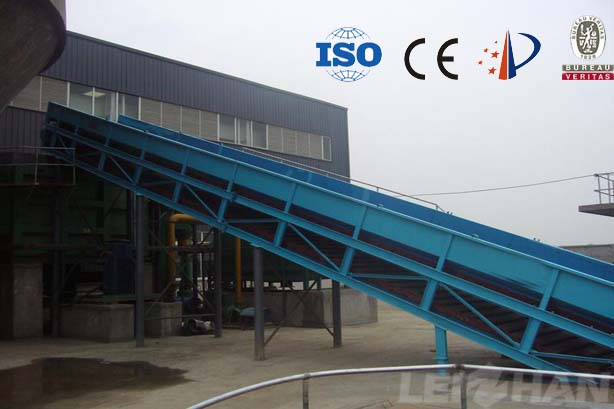

Chain Conveyor In Waste Paper Recycling Line

Chain Conveyor is mainly used in papermaking industry for conveying varies of scattered and bundled waste paper . It can works when it is horizontal or Gradient less than 25°.and it is widely used for padding waste paper from ground to pulper.

Double Disc Refiner For Paper Mill

Double disc refiner is continuous beating equipment for the paper pulp system. According to the requirements of beating technology, Can be used in conjunction with Claflin refiner in series, and single or multiple series, parallel use.

Screening And Fiber Recovery In Paper Pulping Line

Screening and high effect fiber recovery is a challenge for paper making industry, Leizhan continuous upgrade technology to achieve the maximum recovery of fiber, adopt international advance, continuous trial and improvement.

80TPD Wast Newspaper Pulping Project

In order to achieve the recycling of resources, the paper industry prefer choose waste paper as raw material to produce lower quality paper. Use waste newspaper and magazine to produce culture paper in addition to use conventional pulping equipment, also need deinking equipment.

Waste Paper Recycling Pulping Line

A whole sets of waste paper recycling pulping line includes pulping system, cleaner equipment, coarse screening system, fine screening system, fiber fractionating system and Inflow pressure screen before paper machine. Leizhan can supply the whole complete paper pulping line for paper mill, we have many successfully case in home and aboard, such as Iran, Egypt, Bangladesh.

15TPD Kraft Paper Making Project

Leizhan can supply the whole complete Kraft paper making line for paper mill. The whole set of 15t/d kraft paper making line contain waste paper pulping line and 1880 kraft paper machine. Leizhan focus on Paper&Pulp Machine Manufacturing industry 37 years, we provide high quality low price paper machine for paper making friends.

Paper Pulp Screening Machine

Paper pulp screening system contain coarse screen and fine screen, the coarse screen includes M.C Coarse pressure screen, Light impurity separator and Reject separator, the light impurity separator and Reject separator is solve the tailing pulp from coarse pressure screen to reduce fiber loss.

25TPD Toilet Paper Production Line

25T/D Toilet Paper Production Line divides into wood pulp making process and toilet paper making process, high quality raw materials are the prerequisite for the production of high quality toilet paper, so in pulping line generally use wood pulp or white shavings as raw material, but if there is no good paper machine its also difficult to ensure the quality of pulp to meet the requirements of paper, both this is important for papermaking industry.

Vertical Pulper In Pulping Process

Horizontal Pulper and Vertical Pulper is two types pulper equipment in Paper pulp industry, Horizontal Pulper is equipment that used a few years ago, there is no advantage of production capacity and power energy compared with Vertical Pulper, mostly customer choose Vertical Pulper to increase capacity.

10TPD kraft Paper Making Line

Kraft paper widely used in our life, the use of kraft paper determines its high strength requirements, how to make the finished paper into the standard? What equipment can help us to produce high quality and capacity paper with less energy?

70tpd Kraft Paper Machine Supplier

70t/d kraft paper making line contain paper pulping process and kraft paper making process, pulping process divides into top layer pulp and bottom layer pulp, generally top layer pulp use wood pulp, white shavings as material, bottom layer pulp use waste pulp as material. The paper pulp machine and kraft paper machine take a very important role in finished paper quality.

Screening Equipment M.C. Pressure Screen

Before the pulp enter into the paper machine, need to be purified and screening treatment, on the one hand to remove dust and impurities in the slurry, on the other hand make the slurry evenly dispersed, resulting in uniform dispersion of fiber suspension. So that need screening equipment do the appropriate treatment.

Page Links: First PagePrevious50515253545556575859NextLast Page