Cultural Paper Making Line

20T A4 Copy Paper Making Machine

The writing paper production line adopts advanced production technology and equipment, which can help customers achieve high-speed continuous production and improve production efficiency.

Paper Machine Broken Pulper For Paper Mill

Broken pulper is a key equipment for waste paper recycling. Waste paper is a renewable resource. Through the processing of broken pulper, waste paper can be effectively broken down into fibers, impurities removed, and regenerated into high-quality pulp.

20T Copy Paper Making Machine

The copy paper machine can control the composition of the pulp, the uniformity of the pulp, and the pressing and coating processes of the paper during the paper manufacturing process, so that the writing paper produced has high quality and performance.

Copy Paper Production Line For Paper Mill

Are you looking for a reliable and efficient solution to meet the growing demand for high-quality copy paper? Look no further! Introducing our state-of-the-art copy paper production line, engineered to give you an edge in the competitive paper market.

Industrial Paper Production Machine Bale Breaker

Are you tired of wasting valuable time manually sorting and scattering bags for recycling? Don’t hesitate any longer! Introducing a breakthrough innovation, the bale breaker, designed to simplify and enhance your paper recycling process.

Small Scale Copy Paper Machine

Introducing our cutting-edge copy paper machine – the solution for unparalleled efficiency and superior paper quality! We are dedicated to providing state-of-the-art machinery that optimizes productivity and exceeds customer expectations.

Pulp Preparation Machine Light Impurity Separator

Introducing our light impurity separator for stock preparation lines – the ultimate solution for removing impurities and ensuring the highest quality of paper products! Welcome to contact us for details of paper machine.

20T Writing Paper Stock Preparation Line

Writing paper, also known as stationery, refers to specialized paper applied for writing, note-taking, and correspondence purposes. Writing paper machine offers several advantages and details that make it a preferred choice for various writing needs.

Stock Preparation Equipment Vibrating Screen

Vibrating screens are widely applied in various industries to separate and classify different materials based on their size and shape. They offer several advantages and details that make them essential equipment in many applications.

50T/18H Waste Paper Deinking Stock Preparation Line

The deinking stock preparation line is a piece of equipment applied for waste paper recycling and pulping. It can effectively remove ink stains from waste paper and produce high-quality pulp, which is indispensable in paper making projects.

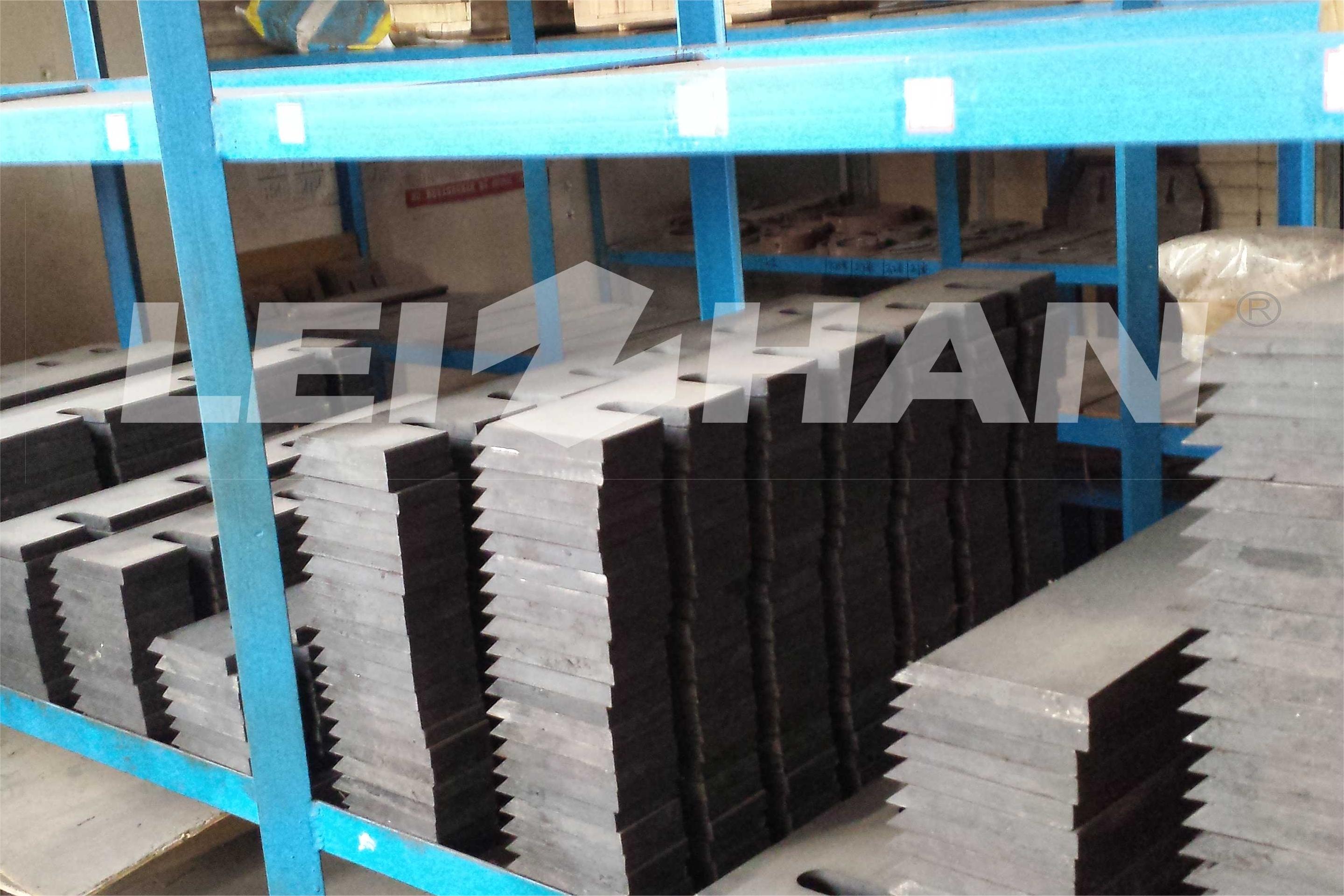

Low Price Doctor Blade On Paper Making Line

The design and use of doctor blade have a great impact on the paper making process and final paper quality. It is one of the key tools to ensure paper quality. You are welcome to consult us for more details.

4300mm Rewinder For Paper Making Line

Rewinders play an important role in the paper industry. It is applied to cut and rewind large rolls of paper in order to produce paper of different specifications and sizes that meet the demand of market.